Hold on and suck in, Miss Scarlett! Removing a plastic corset from a manuscript

What to do with the most treasured document in our personal archive?

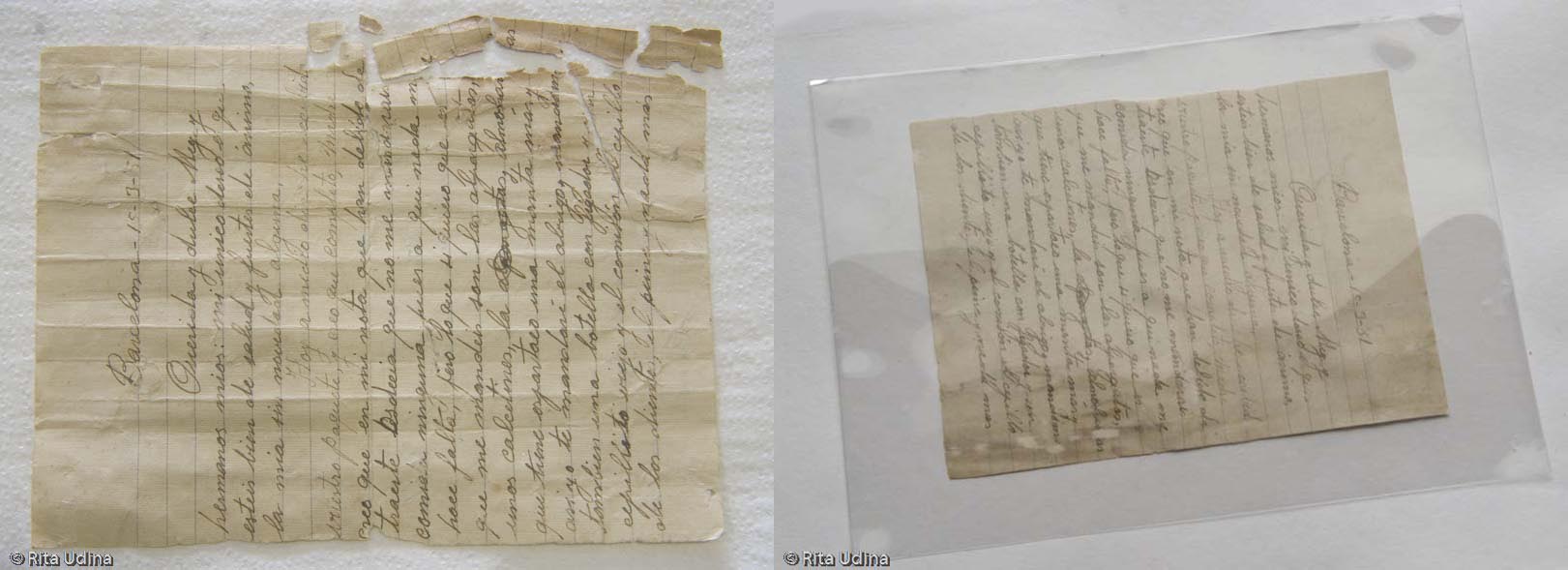

Mrs. Candela kept with love and care a letter that her recently passed away mom [1] had sent from prision, where she was retained for two weeks after joining the 1951 trams strike in Barcelona (link in catalan), during Franco’s dictatorship. A very touching and personal letter, which is also a witness of this historical event.

How to freeze in time this valued mansucript? Thank God Internet gives us good advice: “protect your documents by laminating them“. Plasticizing the document seemed the best option: it would prevent the brittle letter from tears, fingerprints, possible mould damage, tide lines… nothing less than perfect!

But fate had a major mishap against the preservation of this family legacy, because the laminating machine got stuck with the manuscript just inside it. The paper was ejected like a stunted accordion, making it impossible to properly unfold it since some of the folds were stuck with each other. Moreover some paper spots got burnt in the most heated areas.

Left: Digital simulation of how the paper might have entered, and was ejected from the laminating machine. Right: How the letter came out, with folds stuck with each other and losses on the bottom right corner of the manuscript.

Mrs. Candela was horrified because of such an irrpearable loss. Was it possible to undo such a disaster? I was neither very sure about it, being that one the first commitment of such a nature, a real professional challenge!

Plastics

What do conservators know about plastics? We use them under the shape of Reemay®, Hollytex® and Tyvek® (for polyethylene), Mylar® and Melinex® (for polyethylene terephthalate), Teflon™ and Gore-Tex® (for polytetrafluoroethylene, PTFE[2]), and more often than it should be, we come accross biaxially oriented polypropylene (BOPP), polyvinyl chloride (PVC) or even cellulose acetate in the shape of damned sensitive pressure tapes…

I must admit in my mind they were all set under the same label, that boresome section of organic chemistry. The very same section that provides us with both the most useful resources and the most gooey and sticky tapes. No need to say how different they can be!

The first think to know is that there are only two sorts of plastics (sounds easy enough, doesn’t it?): Thermoplastic, which can be deformed without suffering any chemical transformation when re-melted; and Thermoset, that cannot be melted back after being cured.

Laminating pouches and polyethylene terephthalate (PET)

Second learnt lesson, and so much comforting for a conservator and delaminator, is that laminating pouches (or film) are formed by synthetic polymers of the first mentioned kind (thermoplastic). And this let us discern the possibility to transform that disaster into something different, preferrably better. These polymers are (and now the topic becomes slightly cumbersome): polyester, specifically polyethylene terephthalate [3] (PET); ethyl vinyl acetate (EVA) and -occasionally- polyethylene (PE). Laminating film and pouches for documents are widely used and marketed, and therefore there’s an equally wide literature about it, which has quite easen the task [4].

Polyethylene terephthalate constitutes the stiffer part, while ethyl vinyl acetate the stickyest, the inner part of both pouches and film. Ethylvinyl acetate (EVA) is also known as foam, the plastic used to infill conservation boxes.

Delaminating what’s been plasticized

But it isn’t explained anywhere how to deplasticize a laminated document, and at this point a more thorough research was needed, because theory is different from practice. Melting back by heating isn’t a very good idea because of PET’s melting point (500ºF), which surpasses by almost 50 paper’s ignition point (451ºF).

Using solvents seemed to be a more promising option, since literature mentions several possibilities: trifluoroacetic acid (TFA), hexafluoroisopropanol (HFIP), nitrobenzene, dimethyl sulfoxide (DMSO), tetrachloroethane, phenol… among others.

Left: By pairs, plastic samples extracted from the edge of the letter, before (left) and after 24 hours (center) of soaking them in several solvents. Right: Tests in the final stage, with the melted plastic by the solvent action.

Options were significantly reduced when trying to use available solvents, which didn’t acidify nor alkalinize cellulose… neither should they erase the text!

Dimethyl sulfoxide was one of the first ones to try because of its low toxicity. It was tested on a tiny cut made at the edge of the plasticized letter, and it definitly succeeded to separate the two layers. However, when it came to test a spot with paper in between, a thinnest layer of paper -the outer layer carrying the ink and some surface fibres- remained attached to the plastic film. So only the inner part of the paper sheet could be removed, leaving the outer ones stuck on the plastic pouch: a total disaster. I guess we could not undervalue the possible presence of poliethylene, neither the most probable presence of ethyl vinyl acetate, which might be only microns thick, but endangered the whole attempt. After several essays we found the right mixture of solvents. It did not burn the letter, nor acidify it nor make it more alcaline neither it erased or blurred the text. Dissolution should be made warm (120-140ºF), with proper toxic gas protection and most patience.

Removing the plastic film from the manuscript

After removing the plastic film, the letter was washed in water, mended, infilled (since some spots were burnt in the laminating machine) and flattened. Once all these treatments were concluded, it was put inside a Melinex® folder (yes: polyethylene terephthalate!), without any melting or sticking, of course. I just wanted to make sure, in case any further temptation arose, that the reversible one would be used, and not another laminating pouch.

Left: The letter after removing all the polyethylene terephthalate. Right: After the conservation treatment: plastic removed, paper washed, tears mended, losses infilled and final flattened. It is stored in a polyethylene terephthalate folder (no sticking!)

Lamination vs encapsulation

Lamination is a treatment consisting in pasting a reinforcement layer to a support. The reinforcement can either be natural or synthetic based, and since the tissue is adhered to the support its reversibility has limited reversibility.[5] We call it lining when the reinforcement layer is paper based. When the reinforcement layer is a fabric, it is commonly called backing or also marouflage (like in paintings conservation). The fabric can be either natural or synthetic (or a non-woven synthetic tissue such as Reemay®). It is called lamination when the reinforcement is a non-breathable plastic, such as the laminatig pouch of this post.

In summary, and concluding:

- Reversible lining (breathable reinforce + water reversible adhesive) → Yes! (if it actually is reversible).

- Moderately reversible lining (breathable reinforce + solvent or thermo reversible adhesive) → Mmmh…

- It depends on how necessary it is, and if it is properly done. Scarcely reversible lamination (non-breathable plastic reinforce + solvent or thermo reversible adhesive) → Noooo!

An encapsulation can also be made out of breathable media (paper, cardboard, Reemay®, Hollytex®) or either with non-breathable ones (Mylar®, Melinex®); and there is even a mixed option (non-breathable and breathable: Mylar® + Reemay®, o Mylar® + paper). We call them indistinctly folder, housing or encapsulation, although the last one is more used for non-breathable plastics (sealed on the four edges). Encapsulation is 100% reversible because the object is simply stored inside the folder, pouch, encapsulation or housing.

A plastic conservation folder can be very useful to handle very damaged documents, since it provides it a certain stiffness and prevents us from touching it. But we can’t underestimate the risk of condensation (and subsequent microbiological hazard) when the folder is non-breathable in an environement of variable relative humidity (RH) and temperature. As for the rest, conservation folders only involve beneffits.[6]

- Encapsulated with breathable support → Yes! (better when good quality materials are used)

- Encapsulated with mixed supports (breathable + non breathable) → Yes (better when good quality materials are used). Potential drastic HR changes should be minded.

- Encapsulated with non breathable supports → Mmmh… Yes as temporary protection towards handling for consultation. Will it be a permanent storage housing? Have you valued the risk of HR and temperature variations? Consider the possibility of condensation water drops apearing inside the encapsulation… and its consequences.

Hazards of a plastic lamination (plasticizing)

Just in case I wasn’t clear enough: Never laminate a valued document with plastic! Not only it is far too complex to remove: it blurs the text when the surface is scratched, folds and wrinkles on the film are irreparable, it increases the thicknes of the sheet, jeopardizes its digitisation, it can provoke the splitting in diferent layers of the paper if the edges of the film open, it modifies colours, limits (or simply avoids) the possibility of more efficient conservation treatments as well as many analytical tests… But, most of all: it denatures the touch, looks and smell of this ancient suport, paper. Such a sacrilege!

Specifications and considerations on lamination

My suggestion is to leave the idea of shielding documents from everything with a single act (and forget about it), rather than assuming our responsability in their care with simple acts taken along time. Often what is most common sense, is to do what’s been always done: to store the document in a folder, protected by a good quality paper, and most of all, being careful while handling it. As an anti-example for consideration, the case of South Carolina Estate Archives, in which a massive lamination was applied to their most treasured documents, with the cellulose acetate. [7]

This technique is not used anymore because it suffers an acidic degradation (also known as the vinegar syndrome), due precisely to the cellulose acetate. També s’anomena síndrome del vinagre, i ja imaginareu a què fan olor aquests papers.

2017 SERCA Annual Meeting… and why this silly title?!

The reason I chose this silly title is because this content was first presented and fully explained at the SERCA annual meeting (South East Regional Conservators Association (Atlanta, Georgia, EE.UU): Challenges encountered with adhesives and stain removal,(march 3d, 2017), DOI: 10.13140/RG.2.2.36285.97763. I found it hillariuous when I sent the proposal, thinking that in Atlanta everyone had in mind the most famous sentences of the film Gone with the wind. After giving it a second thought, some days before the presentation, I changed my mind, and the title… but I had to face it again when Eva Sander-Conwell introduced my speech with the first given title… so now that I have been embarrassed once, I assume the consequences of this attempt to cheer up potential boring speechs about polymers. Take a look at the facebook album to know more about the event!

Acknowledgement:

Mrs. Candela, for trusting me in such a delicate issue.

Footnotes:

[1] The author of the manuscript is Mrs. Roma Albert Gras (1929-2014).

[2] Purinton, N.; Filter, S.: Gore-Tex: An Introduction to the Material and Treatments. Conservation Center for Art and Historic Artifacts. 20th AIC meeting (American Institute for Conservation), June, 1992, Buffalo, NY (USA).

[3] Funny how polyethylene terephthalate, PET, doesn’t belong to the polyethylene (PE) group of plastics but to the polyesters… Nomenclature says so! PET dates from 1941 and it is the base for Mylar® and Melinex®.

[4] Some references about laminating pouches in particular:

- What is laminating film made out of? ABCoffice™ website, checked February 24th 2017.

- A Closer Look at Laminating Films, FSEA website (Foil & Speciality Effects Association), checked mar. 25th 2017.

And about plastics in general, within the heritage conservation field:

- A curator’s guide to plastics. The Museum of Design in Plastics (MoDiP), checked el Feb. 3d, 2017.

- Compilation of slides and talks about plastics, UK Centre for Materials Education, checked el March 3d, 2017.

- Identification of plastics by looking, touching and smelling, by Carien van Aubel, at the Victoria & Albert Museum blog, checked el Feb. 3d, 2017.

[5] And the reversibility depends not only on the tissue and the adhesive, but also on the characteristics of the reinforced support: which technique and sort of paper, etc. Here a couple of examples of linings made at the studio: with linen, japanese tissue…

[6] Even for the cas of non-breathable pouches or capsules to store acidic paper. Not only because they prevent spreading the acidity to neighbouring objects, but also because this acidity does not accelerate the ageing of the object more than it does when it is stored in a breathable folder. Minter, W.; Baty, J.: The Role of Polyester Film Encapsulation—With and Without Prior Deacidification—On Paper Degradation, Studied Using Long Term, LowTemperature Aging. AIC (American Institute for the Conservation of Historic and Artistic Works), 41st Annual Meeting. 29 May–1June 2013, Indianapolis, IN (USA). Paper Conservator. Research and Technical Studies Postprints., 4, 186-239, 2013., 4, 186-239, 2013.

[7] Further reading

- McGath, M.; Pollei, M.; Baty, J.; Jordan-Mowery, S.; Heslip, S.: Cellulose Acetate Lamination: A Literature Review and Survey of Paper-Based Collections in the United States. Restaurator (num. 4, vol. 36. Decembre 2015). Published online Feb. 2nd, 2015.

- Guidelines for the care of Works on Paper with Cellulose Acetate Lamination. Smithsonian Institution, Department of Anthropology, National Museum of Natural History. Ed. by Marit Munson, with contributions by Jayne Girod Holt,

Susan Peckham, Tara Kennedy and Claire Grundy. Project directors: Carolyn L. Rose and Candace Greene. Checked March 27th, 2017. - McGath, M.; Pollei, M.; Baty, J.; Jordan-Mowery, S.: Cellulose Acetate Lamination: Method and Madness. Gordon Research Conference: Scientific Methods in Cultural Heritage Research, Newry, Maine (USA). July 27th – August 1st, 2014.

- Plenderleith, H. J. The Conservation of Antiquities and Works of Art. Treatment, Repair and Restoration. Oxoford Univesity Press, 1971 (2nd ed. revised from 1951st). Pages 66-67.